Discover the Formed‐in‐Place Foamed Gasket (FIPFG)

Dec 10, 2021

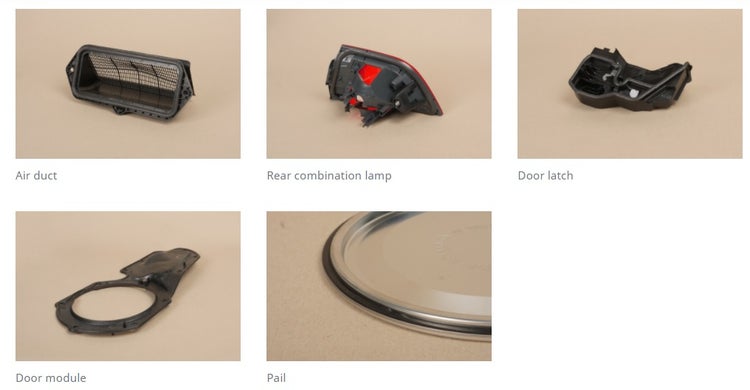

Known as ‘Formed‐in‐Place Foamed Gasket’ (FIPG), Sunstar offers multiple one‐component gasket formulations from the Penguin brand to meet specific requirements for TIER-1 OEM suppliers looking to keep up with the increasing trend of car lightweighting. Our FIPG technology provides a fast and cost‐effective gasket solution. Using our proprietary mechanical foaming machine (FOAMPLY) it enables high‐quality, precise gasket application with low waste, increases productivity and reduces tack time. It’s the fastest and simplest way to seal production parts. Application examples include rear combination lamp, air filter unit, battery cases, door module, door latch and rear gate cover.

It offers fast, low‐temperature curing at 80°C, substantially reducing gasket processing time over conventional methods and outstanding sealing performance. It can be foamed 3 to 5 times the original volume, being significantly lighter than other materials but maintaining an excellent sealing property thanks to the closed-cell-structure Our FIPG foam provides tight, consistent application and excellent water, air, and dust sealing performance and just uses one product, unlike others on the market which require wasteful, and messy pre-mixing. Customers will not need to build up the expertise in its plant, as they get the “ready to use” material and the necessary technology from SUNSTAR.

The Sunstar’s FIPG can be used on three-dimensional and complicated shapes with ease, reduces per unit cost, part numbers and related, inventory costs and facilitates flexible manufacturing as different parts can run sequentially.

Watch how easily can FIPG be applied: https://www.youtube.com/watch?v=Vh5GC3UC6C8