AUTOMOTIVE ADHESIVES & SEALANTS

Paint Shop

- Body Sealer

- Next Generation of Lightweighting

- Underbody Coating

- Strong Cavity Filler

- Acoustic Cavity Filler

Paint Shop Engineered Products

Our advanced lineup of products for the automotive paint shop improve vehicles inside and out, with water‐tight seals, unsurpassed underbody protection and remarkable paintability.

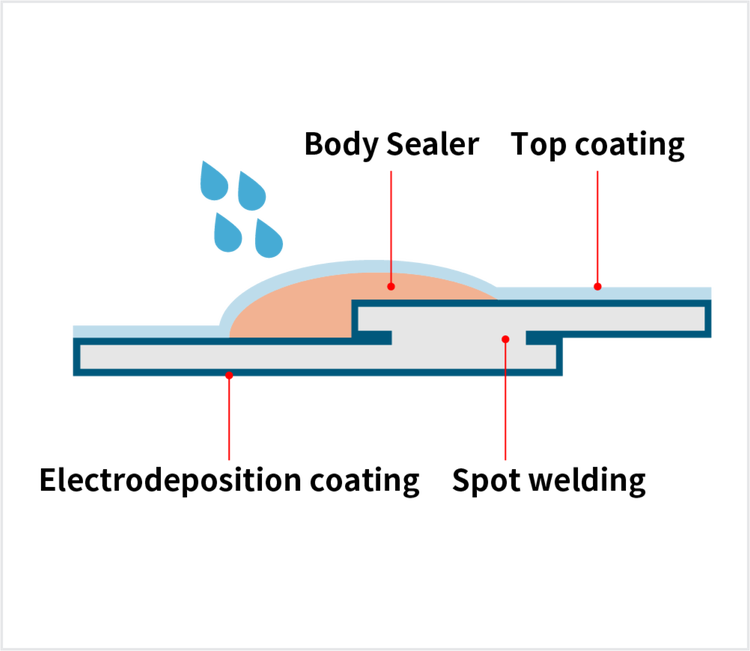

Body Sealer

We offer superior body sealers that provide manufacturers with truly waterproof, dustproof, and corrosion‐proof solutions for automotive body joints that are susceptible to environmental threats. These one‐component PVC sol/acryl sol sealing materials accommodate multiple wet‐ on‐wet coating applications without requiring the time and expense of oven curing between coats. These sealers are tough on the elements, yet easy on your team—and your bottom line.

Distinct Benefits

- Protection at its best. Body Sealer keeps dust and moisture out, preserving the integrity of steel panels inside and outside of the automobile cabin. It puts a durable, rustproof coating on vulnerable steel plate edges, virtually eliminating corrosion.

- Ultimate application flexibility. Body Sealer can be applied manually or robotically during the paint process, then cured in the paint shop’s baking oven.

- Excellent adhesion. Our body sealer is engineered to provide exceptional adhesion, including bonding securely to electodeposition coatings.

- Tailored to your needs. Sunstar’s flexible design allows for the material’s properties and performance characteristics to be optimized for each working environment, application, coating, and working condition. Custom specifications can be set to further fine‐tune coating properties and assure exceptional paint finishing for your shop.

- Excellent compatibility. Our Body Sealer systems are highly compatible with virtually all adherends and paints, and are cured in conventional OEM paint shop baking ovens one time (no need for curing between each applied coating). Achieving excellent results is easy when everything works together.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

*1 Depends on product

Curing method

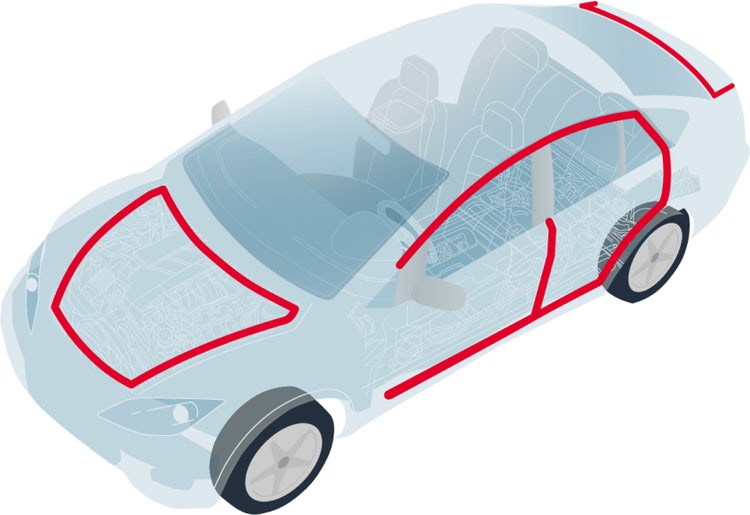

Application parts

Next Generation of Lightweighting

Sunstar’s Next Generation Low Density Sealers

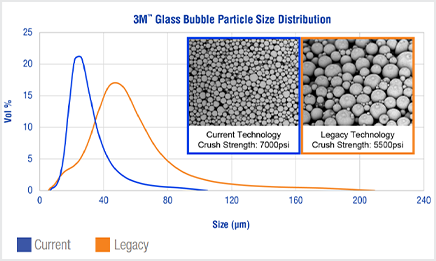

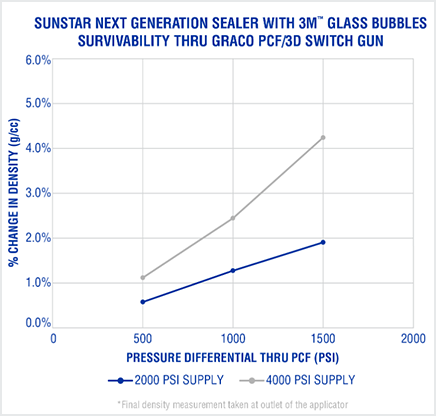

Offer weight savings with superior processability, gap coverage, and Class A paintable appearances for automotive paint-shop applications. Formulated with the 3M™ Glass Bubbles made with current technology, these one component PVC body sealers are designed to retain density and minimize equipment wear under robust processing conditions while also providing high strength, elongation, and adhesion to Electrodeposition coatings on all automotive substrates.

| SEALER ATTRIBUTES | STANDARD DENSITY | NEXT GENERATION | LEGACY SEALER | ALTERNATIVE TYPE |

| LIGHTWEIGHT FILLER | NONE |

3M™GLASS BUBBLES made with current technology |

3M™GLASS BUBBLES made with legacy technology |

POLYMERIC SPHERES |

| DENSITY(g/cc) | 1.3-1.6 | 0.8-1.2 | ||

| DENSITY RETAINMENT* | 100% | ≧98% | ≧95% | <90% |

| CLASS A PAINT SUREACE | YES | YES | NO | |

| EQUIPMENT WEAR* | CONTRDL | ≦CONTRDL | >CONTRDL | ≦CONTRDL |

| WORKABILITY | CONTRDL | CAN BE FORMULATED TO MATCH CONTROL | ||

| MULTIPLE SEALING APPLICATIONS | YES | YES | NO | |

* Density Retainment and Equipment Wear as dependent on certain process parameters and equipment

Product Types

Paintable and non-paintable:

- Seam Sealants

- Hem Sealants

- Roof Ditch Sealants

- Underbody Coatings

- Universal

3M™ Glass Bubbles

| Legacy Sealer | Next Generation | Standard |

|

|

|

Legacy sealer vs Next Generation Lightweight Sealers vs Standard Density Control – Painted with OEM Primer

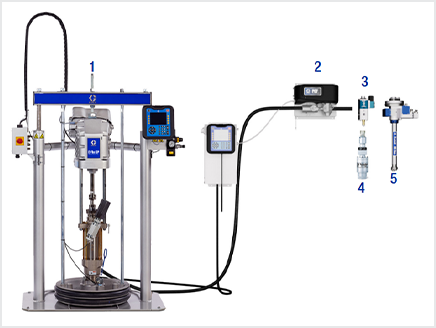

Recommended Equipment Configuration

Graco Switch 3D Gun with Slot Tips

Pros:

- Consistent slot stream thickness from edge to edge

- Performed the best in gap coverage tests

- Ability to dispense from 3 different tip configurations gives flexibility in programming robot paths to optimize cycle time

- Tip seal shut off for clean start and stops

Cons:

- Have to be close to the substrate (7 – 10 mm) for best quality

Switch 3D Gun

Graco Switch 3D Gun with Slot Tips

Pros:

- Can be programmed to dispense at a distance from the substrate, allowing for better clearance from objects on car body

- Simple robot programming for most motion paths

Cons:

- Harder to program robot paths with tighter clearance restraints since an offset is required for pattern width

Precision Swirl

1. Electric supply system 5-300 gallons

2. Precision Continuous Flow metering & dispensing systems (PCF)

3. iQ-S Snuff-Back Valve

4. Precision Swirl Orbital Sealant Dispensers

5. Switch 3D Gun High-Pressure Rotary Applicator for Automotive Sealin

In collaboration with

For warranty and product information, refer to material and equipment supplier information.

Underbody Coating

The underside of an automobile is subjected to a pounding from stones, debris, road grime, moisture and corrosive agents such as road salt and brine. Sunstar Underbody Coatings— available in both thin film and foaming types—are designed to provide a critical protective barrier between the road and vulnerable underbody surfaces. In addition to protecting from moisture and impact, the foaming‐type products provide excellent sound dampening properties.

Distinct Benefits

- Tailored to your needs. Sunstar has engineered a solution with diverse manufacturing needs in mind. Our underbody coating has been developed to be tailored to varying processes and working conditions, providing optimum performance for each unique environment, application, and condition present in regions around the world.

- Low weight. High performance. Although our thin‐film type underbody coating has a thinner application and a lower specific gravity, it delivers the same performance as thicker, heavier coatings thanks to its advanced formulation.

- Lower cabin noise. Our flexible foaming‐type underbody coating provides a tough, sound‐deadening barrier that reduces stone and cinder noise, contributing to a more comfortable, quiet driving experience.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

*1 Depends on product

Curing method

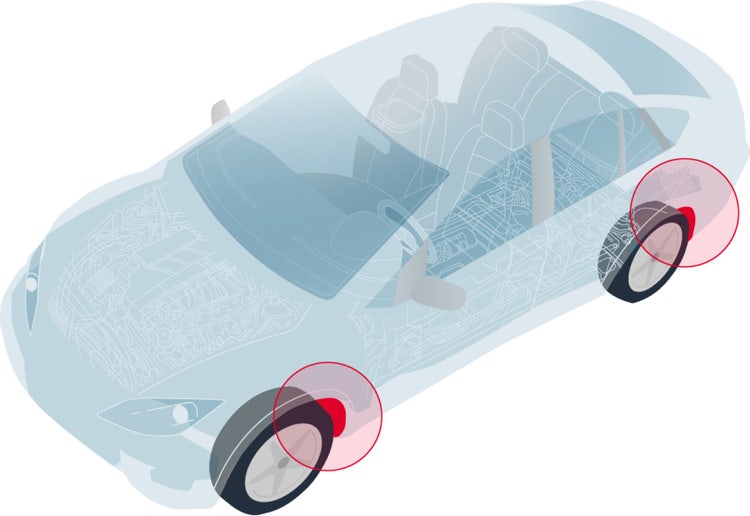

Application parts

Structural Cavity Filler

Sunstar leads the way with advanced products for the automotive paint shop, including high‐ performance gap and cavity fillers engineered to improve automobile structure rigidity while also reducing vehicle weight.

Distinct Benefits

- A wide range of products. Structural Cavity Fillers are available in a wide range of foam expansion ratios to assure the right filler for the right application. Cartridge type products are available for manual application.

- Excellent filling property. The unique low‐drip, high‐build formulation delivers exceptional gap filling performance.

- Simple curing process. As a two‐component mixture‐type product, these fillers do not require ovens or UV lamps to accelerating curing.

- Non‐polluting. Structural Cavity Fillers do not contaminate electrodeposited surfaces and are designed to promote coating quality.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

Curing method

Application parts

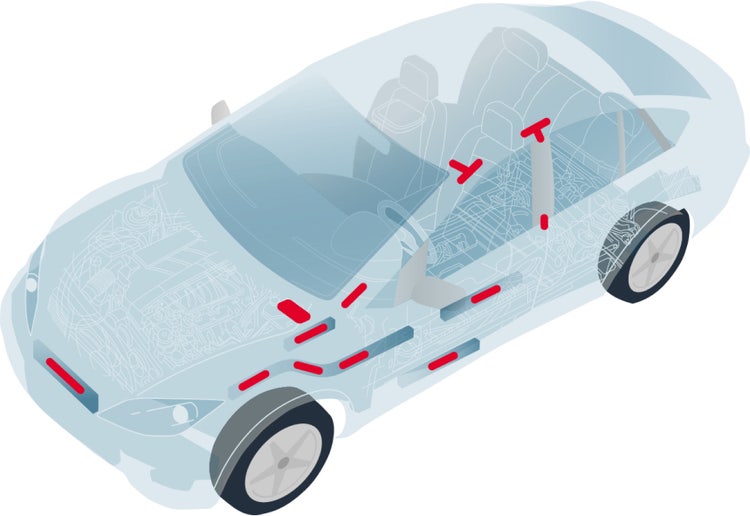

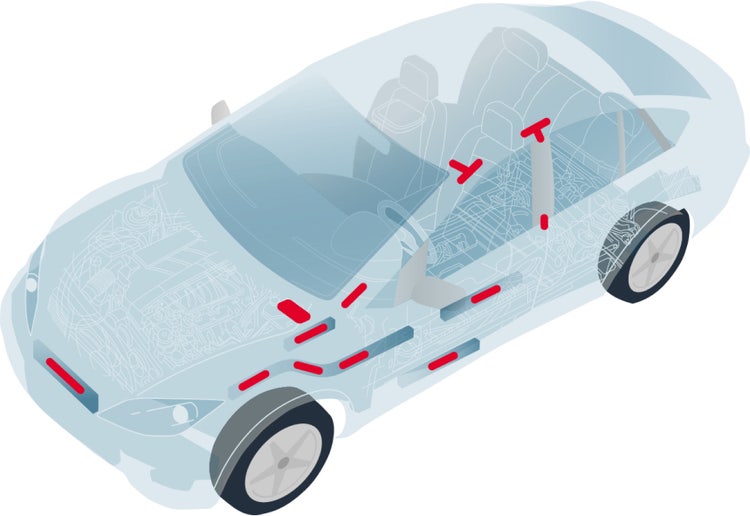

Acoustic Cavity Filler

Sunstar’s Acoustic Cavity Fillers are engineered to dramatically improve sound insulation and vibration damping. These fillers close the gaps and cavities throughout the automobile body that commonly generate unwanted noise and resonance.

Distinct Benefits

- Excellent filling properties. The unique low‐drip, high‐build formulation delivers exceptional gap filling performance.

- Superb sound insulation and vibration damping. The properties of Acoustic Cavity Fillers were developed specifically to suppress the noises and resonations that can detract from the driving experience. The result is a quieter, more enjoyable cabin.

- Uncompromising. These fillers have been developed to be highly compatible with electrodeposited surfaces, preserving their integrity along with top coat quality.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

Curing method

Application parts

We’re ready to help

Contact us to find out how our advanced engineering solutions can help your business

Trusted by the world’s leading companies to solve unique engineering challenges

Your innovation partner

chosen by the best